Laser Scanning 101: How It’s Done and What It’s For

In this article, we explain how laser scanning works, the options for customization it presents, and the contexts in which we have deployed it for our clients. We believe so strongly in the method that we’ve written an entirely separate article all about its benefits. Here, though, we provide the basics:

How It Works

Laser scanning, specifically LiDAR (Light Detection and Ranging), is a cutting-edge technology that’s used to create highly accurate mappings of indoor and outdoor spaces. Perched on a tripod, the laser scanner performs a full 360-degree scan upon the push of a button. During this scan, it emits up to 2 million laser “pulses” per second. Each pulse, paired with a mirror and sensor, is used to capture the location and distance of a discrete point in space. The sheer quantity of laser pulses results in an extremely high image resolution – depending on the size of the space being measured, the distance between points can be as low as 1 millimeter. This means that the scanner can capture surface irregularities and contours that might have otherwise gone unmeasured.

As powerful as LiDAR is, it has two important limitations that necessitate careful planning: it can’t measure the floorspace that’s directly underneath the tripod, and it can’t scan through hard surfaces. With these in mind, the scanner operator typically has to perform a series of scans in order to create a full picture of the space or structure being captured. The number of scans will depend on the size and segmentation of the overall space being measured: a three-bedroom house, for instance, will require far fewer scans than a 200-room hotel.

Each individual room typically requires two scans: one taken from the center of the room, and another taken from an entrance or exit that can be used to stitch the individual room scan into a larger whole. This second position’s scannable area must have at least 50% overlap with the previous area scanned to ensure that the two scans can be seamlessly stitched together. Once those two scans are taken, the scanner is moved to an adjoining room or hallway to continue scanning the entire structure. The composite image of multiple scans, which is made using specialized software that can stitch together hundreds of overlapping scans, is called a point cloud. Once created, a point cloud can be used to render comprehensive architectural drawings, including plans and elevations, or full Revit models.

The efficiency and accuracy of this method cannot be overstated. Using our Leica RTC360 scanner, we can typically scan an entire 200-room motel in less than a day, or a 6,000 sq. ft. home in less than half a day. Both of these undertakings would typically have taken days to measure manually, for a far less accurate end product.

Color vs. Standard

When opting for laser scanning services, clients can choose between standard or color scans. Standard scans meet most client needs by providing a detailed, black-and-white point cloud. If a color scan is desired, the scanner can perform an additional rotation using its HDR camera. This photographic data is automatically overlaid onto the scan, creating a color image that accompanies the standard point cloud. Since it technically requires twice as many scans, this option comes at a slightly higher cost, but it’s ideal for projects that demand chromatic specificity.

Potential Applications

Laser scanning has a wide range of potential applications for both new construction and existing buildings. In our own work, we have deployed laser scanning for the following purposes:

- New Builds: By laser scanning a build site, architects can generate survey-grade site models in Revit. Whenever designing a new build for a client, we first generate a point cloud of the existing terrain to ensure that the design will fully account for the lot’s shape, size, and topography.

- Building Analysis: Our 90 Madison Plaza project used a point cloud to render accurate layouts for all office suites and common areas in a seven-story office building. We then used this to conduct a comprehensive Building Owners and Managers Association (BOMA) analysis, which provided the client the information they needed to confidently update and expand the building’s rentable square footage.

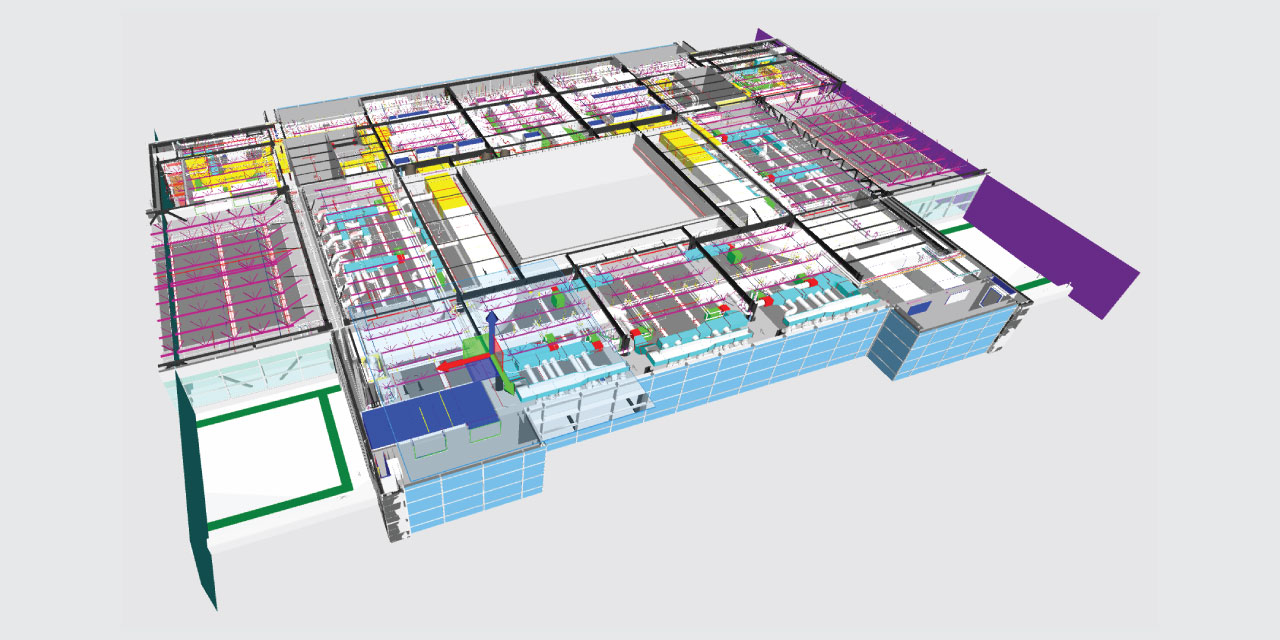

- Repurposing Space: When repurposing or renovating an existing space, a comprehensive as-built rendering will capture all of the imperfections and variations that are not accounted for in the original plans. A large hardware chain used our laser scanning services to capture five tenant spaces that it would later combine into one large retail outlet. The point cloud rendered by the laser scan would prove essential for shelving layouts, MEP design, and code compliance studies.

If you’re interested in learning more about how laser scanning can help your project achieve new heights, you can reach out to us here. Or you can take a look at our article that goes into the several advantages that laser scanning presents compared to the alternatives.

NOTES

- We’re talking about Laser scanning in the context of measuring buildings (architectural as-builts)

- A list of what we do

- No upper limit in the size of what we can scan

- There is a lower limit in the size of what we can scan. Won’t scan anything smaller than a car.

- the limits of the equipment, what it can and can’t do

- LiDAR – Light Detection and Ranging

- The process: put the scanner on a tripod, hit the go button, and it does a full 360 degree rotation

- Starts spinning, shoots out 2 million lasers per second

- Each laser has a mirror and sensor associated with it.

- Measuring everything in the room except for what’s directly underneath it

- The lasers can’t go through anything solid

- Giving you a physical model of the dimensions of the room. Won’t go through furniture.

- Generates raw data that’s a large collection of points relative to the scanner

- Hundreds of scans are stitched together to create a point cloud through specialized software. We use that to render floorplans and/or Revit models.

- Can do point clouds in full color (scanner has an HDR camera on it)

- For color scans, the initial scan data is in black and white, then the scanner will do another rotation with the camera, and overlay the photo over the scan data.

- Color scans cost more.

- Revit can take a consolidated point cloud and import it natively.

- The scanning process is extremely fast: 200-room motel in 3 hours. 6,000 sq. ft. home in 2 hours. These are for jobs that previously would have taken days. It’s far more accurate than manual measurements; the same cost, though, due to the cost of the technology itself. Sometimes it’s cheaper if he has to travel to the client (hotel costs, etc.)

- At least 50% overlap between each scan is essential, as it enables layering/combination of scans into one complete, contiguous scan. Through repetition the technology makes the connection between separate scans.

- No need to touch any part of the buildings being measured – great for preservation. Also no need to purchase potentially expensive equipment for specifically difficult measuring tasks, such as a scissor lift to measure high ceilings.

- Less need for prep – he really just needs access to the spaces that are to be measured (no locked rooms, etc.)

- You can scan with people there – even if there’s a person in the initial scan, you can do a double-scan that can automatically remove them, though there’s little need for that.

- Some clients will want a very clean point cloud without people, in which case you shoot on a day when no one is around.

- Typically, a single room like a bedroom will require two scans – one in the middle of the room and one in the doorway to offer enough

- For building exteriors, take 15-20 different scans to get the full building panorama

- Doesn’t need to be survey-grade accuracy.

- Potential applications:

- NEW BUILD: By doing a laser scan of the existing terrain, we were able to bring an extremely accurate site model into Revit to begin our design and tackle the challenging lot. By taking full advantage of the lot’s unique shape and size, we were able to craft a house that fulfilled every single one of the client’s wishes for their forever house.

BUILDING ANALYSIS: Located in the trendy Cherry Creek neighborhood, 90 Madison Plaza is a seven story office building that has been in the same family for generations. For many years, they had based their rentable square footage values on old, outdated drawings that didn’t accurately reflect the current layouts of the office suites. Denver Drafting & Design was hired to perform a laser scan of the building, provide new, accurate layouts for all the office suites and common areas, and perform a thorough BOMA analysis.

REPURPOSING SPACE: For this project, a large, national hardware chain was looking to take over five existing tenant spaces, combining them to create one large space for their next outpost. In a project like this, it’s imperative that the as-builts are accurate, as the incoming retailer will need to do shelving layouts, MEP design, code compliance studies, and more to ensure that the new store will conform to their exacting standards. A complete laser scan provided the needed accurate layout.